DL Chemicals invests €30 million in Belgian manufacturing

At DL Chemicals, we strongly believe in the power of local production. We’re proud to reinforce that belief with two major infrastructure projects in the heart of West Flanders: the opening of our brand-new, fully automated DLC3 production site in Wielsbeke, and the complete renovation of our office building at our Waregem site. These projects represent a combined investment of over €30 million.

They reflect our long-term vision for sustainable growth, innovation, efficiency and job creation.

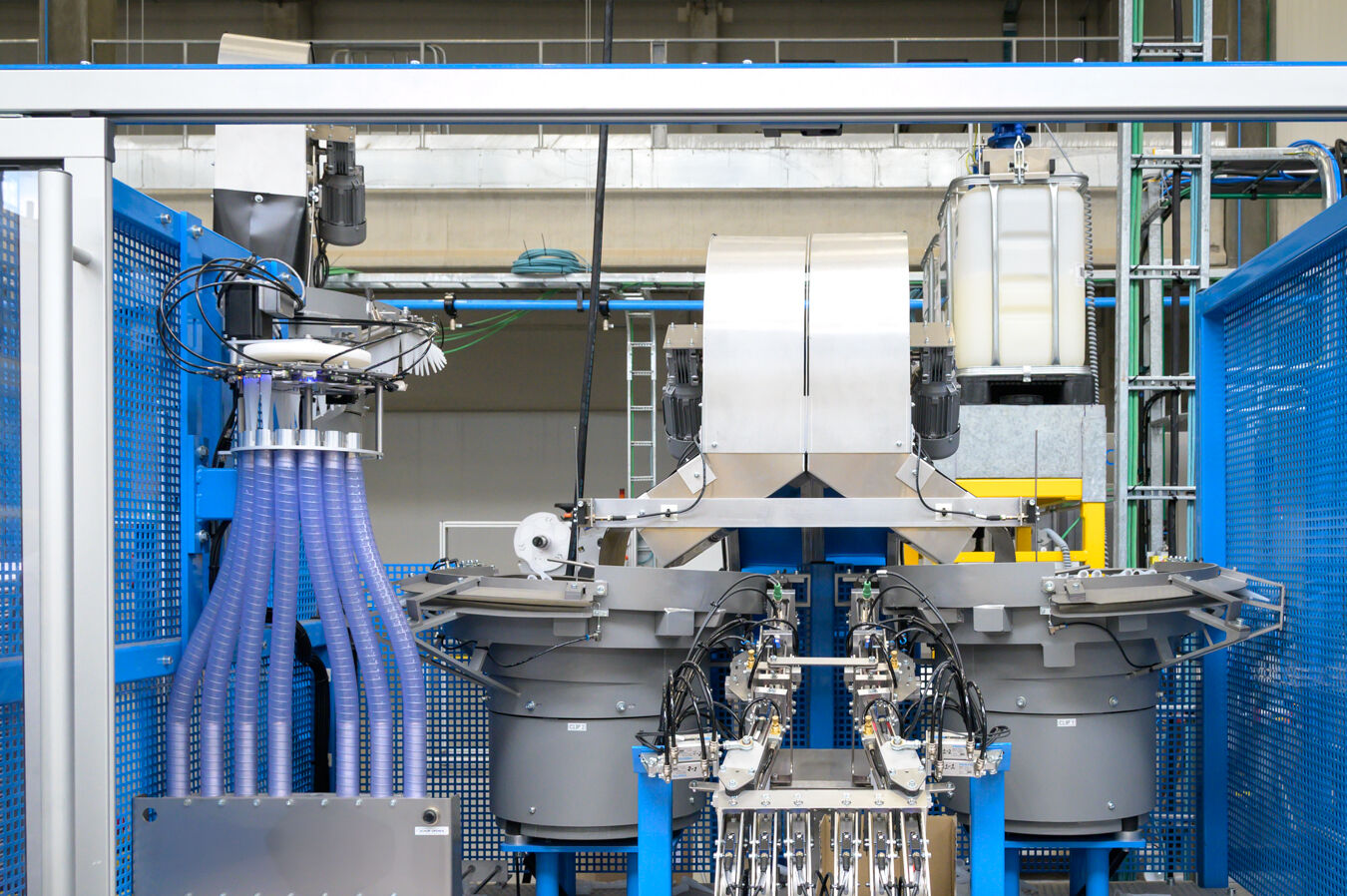

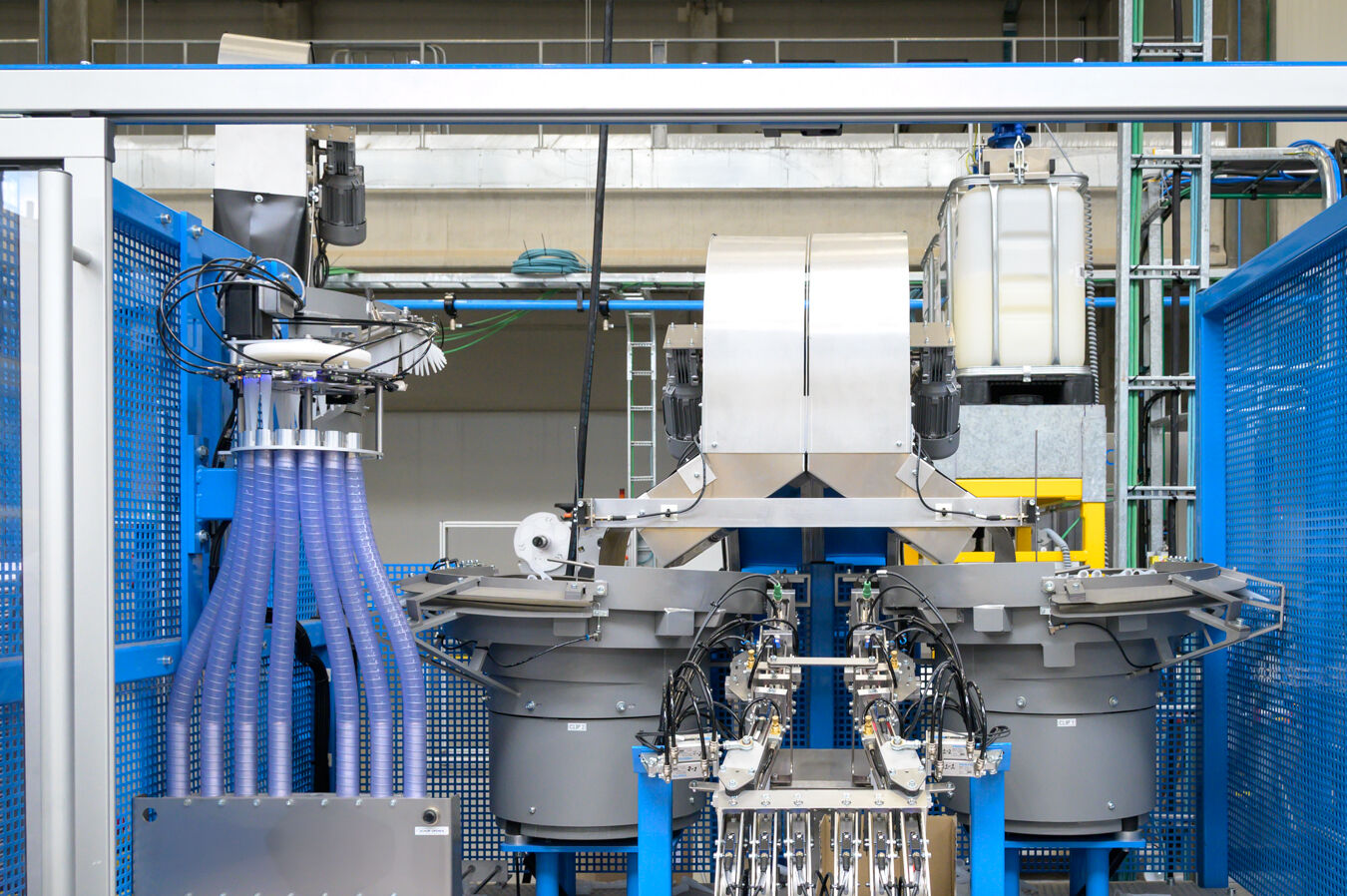

DLC3: Smart and future-proof production

With the launch of DLC3, we are significantly expanding our production capacity. The new site is dedicated exclusively to silicone sealants, with a focus on large volumes.

Built to the highest safety and environmental standards, DLC3 offers a fully automated process that ensures consistent quality, reduced waste, and maximum efficiency. Raw materials are supplied in bulk via silos and tanks, and the sealed system guarantees hygiene from start to finish.

Today, DLC3 increases our total production capacity by about 50%, with the potential to double that output in the future.

Flexibility through automation

Mixing, dosing and filling are fully automated. Thanks to intelligent processes, it is possible to quickly switch between different products or specific customer requests – essential for our flexibility, the cleaning process can be reduced to a minimum and production planning can be made extra efficient.

DL Chemicals sealants and adhesives are distributed in more than 50 countries, mainly under the well-known professional brands Parasilico and Parabond and Rexon for the DIY market.

A sustainable investment in the future

With air purification areas, a NO2 installation to prevent curing during production interruptions, and provisions for future supply of raw materials over water, DLC3 proves itself as a future-oriented site. Both the building and the processes are designed to perform over the long term and to continue to grow with the needs of our customers.

“At DL Chemicals, we believe in continuous improvement, sustainable innovation and long-term partnerships. By producing in Belgium, we maintain control over quality, service and speed. DLC3 is the perfect proof of that. This investment enables us to serve our customers faster, more efficiently and more flexibly than ever before,” says the management team of DL Chemicals.

Waregem: modern workspaces on familiar ground

We’ve also modernised our long-standing Waregem site with a new, energy-efficient four-storey office building. Since April, our production-support staff have been enjoying a comfortable, modern workplace—another investment in our people and our future. Investments were also made in the production department itself in Waregem, with a new mixing machine for rigid products such as Parabond adhesive sealants.

Photos: Ursy Claeys

Next year, we’ll proudly celebrate 90 years of DL Chemicals—a milestone of trust, quality, and manufacturing excellence.

Excellence in sealing and bonding—today, tomorrow, and for the next 90 years.