Roofing

Below you will find general guidelines and info on how to install a flat roof. For each step we advise which products can be used. The specific methods and guidelines per product can be found in the technical sheets. Be sure to also check out our brochure and the frequently asked questions about this application!

1. Roof types

The primary function of a roof is to protect a building or the space beneath it from water infiltration. When choosing the right type of roof, it is essential to minimize the risk of leaks and their damage. In addition to ensuring the watertightness of a roof, several other considerations come into play, including insulation, safety (e.g., fire safety), environmental impact, technical capabilities and limitations, aesthetic preference, specific use of the roof, regulatory compliance, budgetary considerations and the promotion of sustainable construction.

Pitched roof

A pitched roof is made waterproof by covering the roof with a fragmentary layer of discontinuous materials (tiles and slates) that overlap each other. Roof insulation can be placed along the outside or inside of the roof floor. Another option is to insulate the attic floor.

Flat roof

A flat roof does not necessarily have to be exclusively horizontal, but can have -even a steep- slope. It is recommended that every flat roof have a slope layer with a sufficient gradient (±2%) to allow water to drain to the water drainage point.

Roof insulation on a flat roof is installed, after installing a vapor barrier:

- The most common and recommended installation technique is that of the hot

flat roof. Here the insulation is placed on the outside of the roof floor. - With a cold flat roof, the insulation is placed under the roof floor. This technique

is no longer recommended. - With an reversing roof, the insulation is placed loosely on top of a sealing layer

and the use of a vapor barrier is not necessary, as that function

is taken over by the sealing layer. A ballast layer must be applied on top of the

insulation.

Flat roof waterproofing is done with a continuous waterproofing membrane of bituminous, synthetic, liquid or metallic nature.

- Bituminous roof waterproofing is applied in 1 or more layers of polymeric bitumen (APP or SBS) and is always reinforced with glass fleece or polyester. A goxified bitumen may be used as an underlayment if necessary.

- Synthetic sealing is applied in one layer and is based on elastomers (EPDM), thermoplastic elastomers (TPE) or plastomers (PVC). This with or without reinforcement and/or caching on the underside of the sealing layer.

- There is also the use of liquid seals (PU, SMP, etc.) or metal roof seals.

2. Installation of bituminous flat roof

Installing flat roof insulation

Using Parafoam Panelglue NBS offers an effective solution for bonding insulation panels, especially in applications such as hot flat roof installation. By securely bonding the insulation layer, the risk of cracking, tearing and potential leaks is significantly reduced. This keeps the roof structure protected under the insulation layer, ensuring durability and reliability. More information about applying adhesive foam on insulation panels can be found here.

In addition to its protective function against cracks and leaks, the insulation layer acts as a heat buffer, resulting in energy savings. The absorption of solar heat during the day and its release at sunset contribute to more efficient energy consumption.

When installing the insulation layer, the application of a vapor barrier on top of the slope layer is critical. This vapor barrier prevents condensation moisture from penetrating the insulation material, which enhances the durability and effectiveness of the insulation layer. The use of synthetic cold adhesives, such as 1C PU, 2C PU, or bituminous cold adhesive, is the usual method of attaching the insulation.

Since the waterproof finishing layer is applied on top of the insulation, Parafoam Panelglue NBS plays an essential role in ensuring reliable and durable installation of insulation panels.

Find more information on How to install insulation on your roof here.

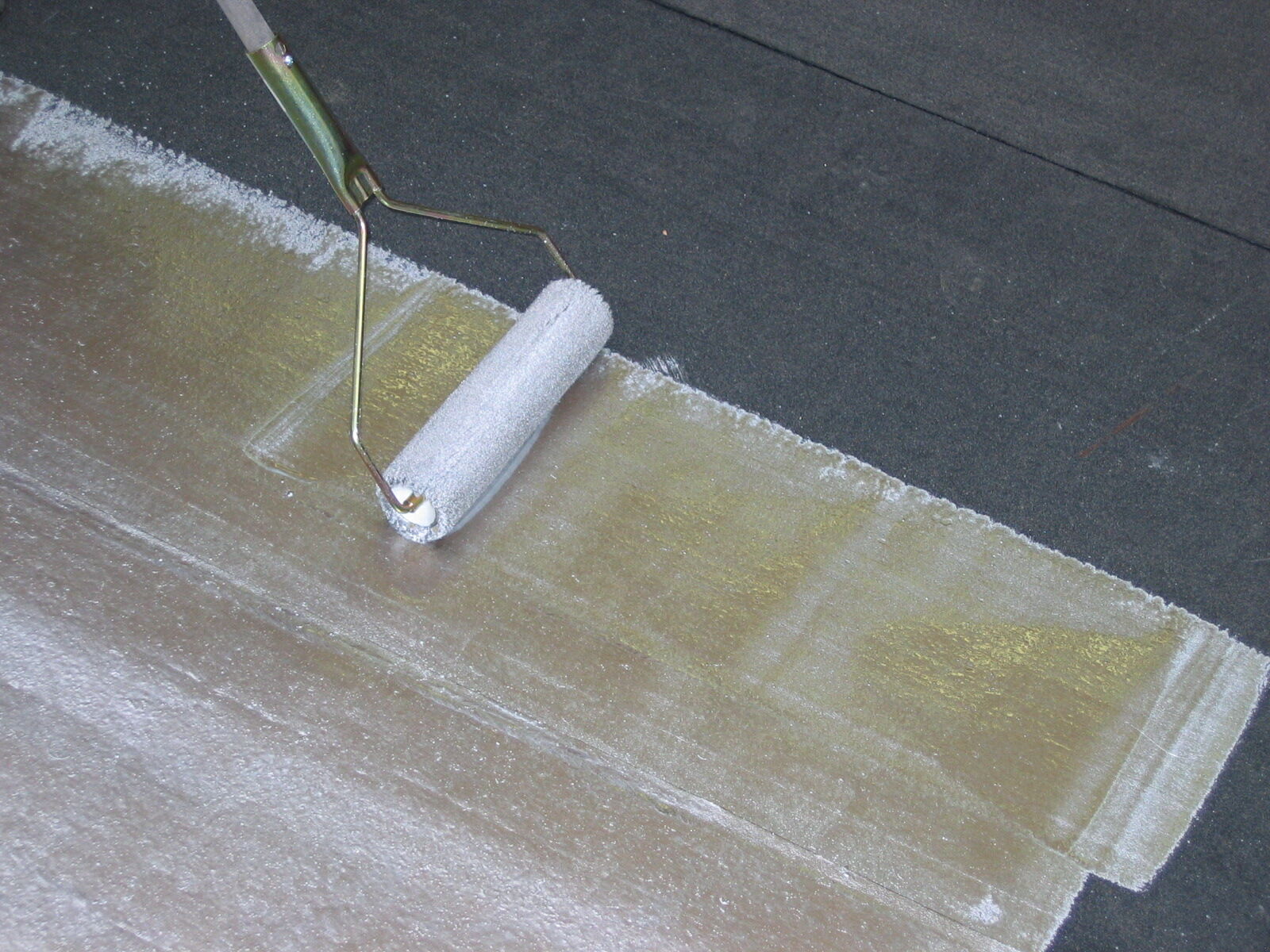

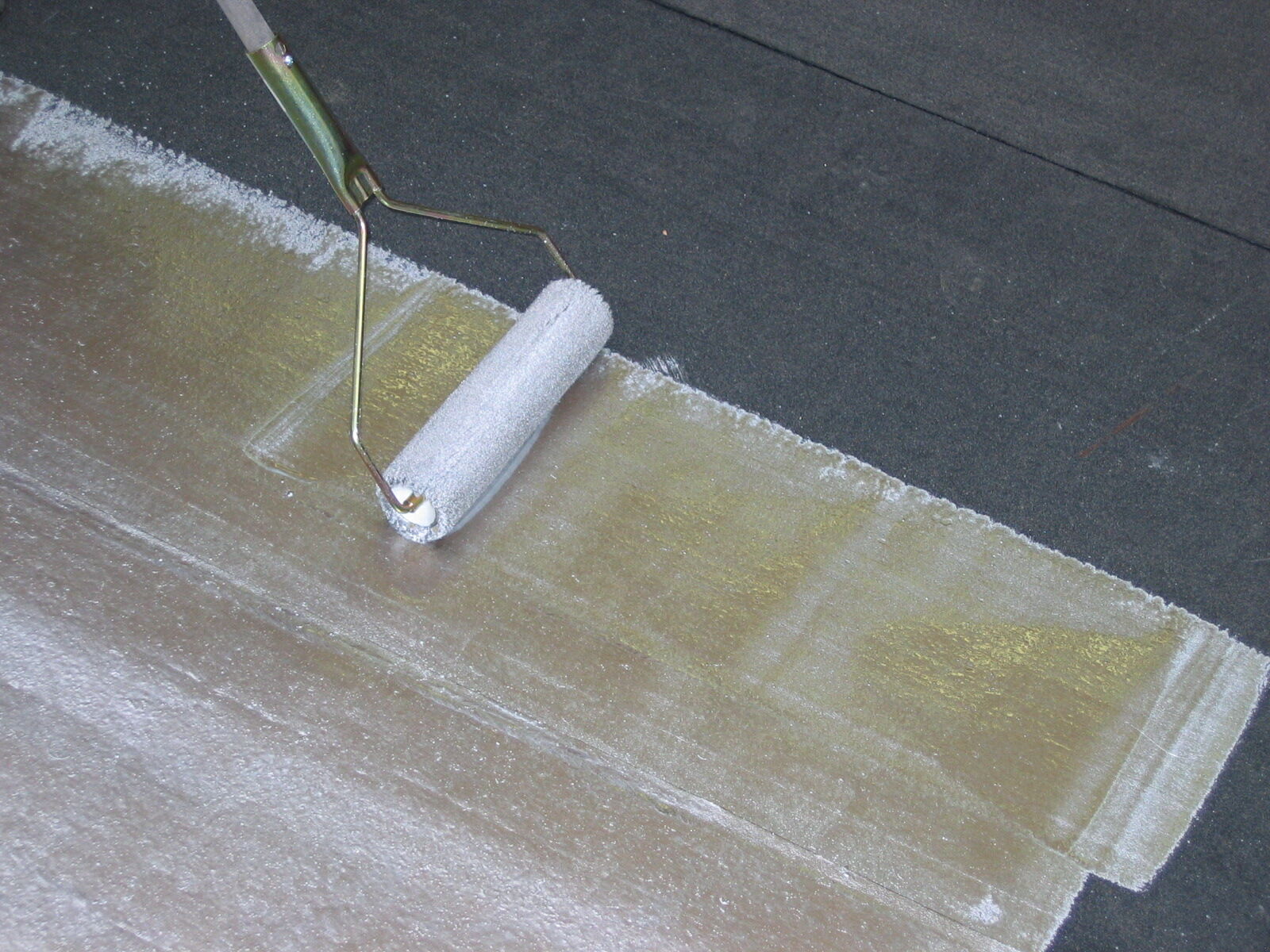

Priming the substrate

When it comes to applying a vapor barrier or bituminous sealing layer, there are situations where the application of a bonding primer to the substrate is strongly recommended. This is particularly the case with highly absorbent or unevenly absorbent substrates, as well as brittle or dusty substrates.

This is where Pararoof Quick Primer comes in. This primer plays an essential role by activating the substrate, preparing it optimally for the installation of the bituminous sealing layer.

Cold bonding of roof membranes

A bituminous waterproofing of a flat roof consists of one or more layers of finish, with the top layer consisting of polymeric bitumen and polyester reinforcement. The finishing layer must have a certificate of suitability for use. The bituminous seal can be attached via flame welding, for example. However, an easy and fire-safe way is to use Pararoof cold glue where the finishing layer is glued to the substrate.

2. Protection of bituminous flat roof

Reflectective coating layer

Although bitumen roofing offers many advantages, it is important to note that bitumen is naturally less resistant to UV radiation. Over time, this can lead to damage to the bitumen layer, which increases the risk of leaks. To give bitumen additional beneficial properties, polymers are added.

Applying a reflective coating layer, such as Pararoof Reflex, to bituminous roofing is an innovative approach to protecting flat roofs. This type of roof coating not only protects the underlying bitumen layer, but also provides additional benefits.

By efficiently reflecting sunlight, roof temperature rise is significantly reduced, resulting in reduced cooling demand during the summer months. Moreover, the improved performance of solar panels on such roofs provides a remarkable increase in efficiency, up to 15%, while extending the lifetime of photovoltaic systems. This translates into increased energy generation and significant cost savings over time.

4. Renovation of bituminous flat roof

Should wear and/or blistering occur despite protective measures of the bituminous roof, the roof must be repaired to extend its life. A first option is to apply a renovation layer that has a nourishing and repairing function. If the wear has gone too far, it is necessary to apply an additional layer of bitumen. In both cases, the procedure is the same:

- Clean the existing surface so that it is clean and flat

- Repair blisters by cutting them open, drying and sealing them and repair possible cracks and fissures with Pararoof Super

- Apply a bituminous primer (Pararoof Quick Primer)

- Apply a renovation layer(Pararoof Renovation) or a new bituminous layer and seal with Pararoof Bitumen or Pararoof Super

If an insulation layer is not yet present, it can still be installed when renovating the flat roof (inverted roof method).

5. Finisching touche of your roof

After applying a waterproofing layer on a flat roof or when installing roofing on a pitched roof, meticulous detail finishing is critical. Improperly finishing or neglecting seams, gaps and transitions between materials on the roof and roof details can cause leaks and moisture problems.

In this regard, several products play an essential role in creating waterproof and durable finishes for complex roof details:

- Pararoof Seal: This product enables a quick and waterproof finish to complex roof details such as upstands, domes, skylights, gutters and chimneys.

- Geotextile: Serves as a reinforcing coating at cracks, joints and edges, providing additional durability and stability.

- Parasilico EPDM: Used for bonding and finishing EPDM coverings, contributing to a reliable and long-lasting seal.

- Parasilico Lead: Ideal for aesthetic finishing of all lead components on roof and facade, ensuring both visual appeal and functionality.

- Pararoof Bitumen: This product is suitable for the repair of bituminous roofs and the waterproof detailing of joints, seams, eaves seals, skylights and rainwater drains.

- Parabond Zinc: Designed for bonding, installation and finishing of gutters, ridge tiles, zinc sheets, cornices and emergency overhangs, to ensure a high-quality and watertight finish.

- Paracol Tuile: This product is used for smooth bonding of hollow roof tiles to each other, to wooden battening and cement fiber boards, as well as for sealing joints between building elements.

These products provide technical expertise and high-quality solutions to achieve waterproof and durable finishes, effectively protecting complex roof details from leaks and moisture problems.

More info on the different methods of application and choice of our products can be found through our roofing brochure